Industrial Dust Control

There are a large number of industrial processes whose dust emissions are regulated including earthmoving and excavation, crushing and milling operations, material handling, cement manufacture, recycling and demolition, as well as power generation.

There are a large number of industrial processes whose dust emissions are regulated including earthmoving and excavation, crushing and milling operations, material handling, cement manufacture, recycling and demolition, as well as power generation.

One of the reasons that require dust emissions to be controlled are the health effects. Dusts can cause a variety of diseases, not only to those who are working in dusty environments on a daily basis but also for those who reside around mines and factories that produce dust emissions. The Occupational Safety and Health Administration (OSHA) is the federal agency responsible for ensuring that workers at non-mining facilities are protected from exposure to dusts.

How to Control Industrial Dust

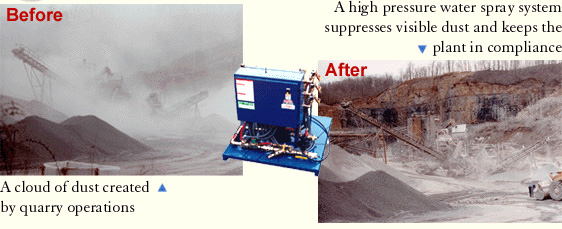

NESCO's Dust Control Solutions; high pressure spray system controls visible emissions, keeps dust out of the neighborhood and away from your workers.

DustPro Spray Systems:

Features: remote electronic control, and heavy-duty construction, 200psi pressure operation. DustPro pump modules are "state-of-the-art" and can be fully automated or equipped with air and glycol purge systems for cold weather operation. Guaranteed to comply with SubPart 000 or other applicable NSPS. Available in 10 to 100 gpm capacities.

The DustBoy:

Features: Smaller crushing or recycle plants processing less than 500 tph. Pumps include a strainer, TEFC motor, and Nema 4X control panel. Available in 10 or 20 gpm capacities, manually controlled.

|